Siffofin samfur

1. High muhalli kariya matakin

Za a iya samun zaɓaɓɓen etching ba tare da amfani da samfuran barasa kamar IPA ba.

2. Low samar kudin

Adadin kari yana da ƙasa kaɗan, lokacin rubutu kawai yana ɗaukar mintuna 6 zuwa 8, kuma farashin ya fi ƙasa da tsarin rubutun IPA.

3. Mahimmanci inganta ingantaccen aiki

Idan aka kwatanta da tsarin rubutu na IPA, daidaiton rubutu da kuma tunani sun fi kyau.

4. Babu farkon polishing tsari

Farashin yana raguwa sosai, kuma ƙari kanta ya fi dacewa da muhalli.

Ma'aunin Fasaha

| Abubuwan da aka tsara | Abubuwan da ke ciki | CAS No. | EC No. |

| Ruwa mai tsafta | 95-97% | 7732-18-5 | 231-791-2 |

| Sodium lactate | 2-2.5% | 532-32-1 | 220-772-0 |

| Sodium epoxysuccinate | 1-1.5% | 51274-37-4 | / |

| Surfactant | 0 .01-0 .05% | / | / |

| Preservative acid | 0 .1% - 0 .2% | 137-40-6 | 205-290-4 |

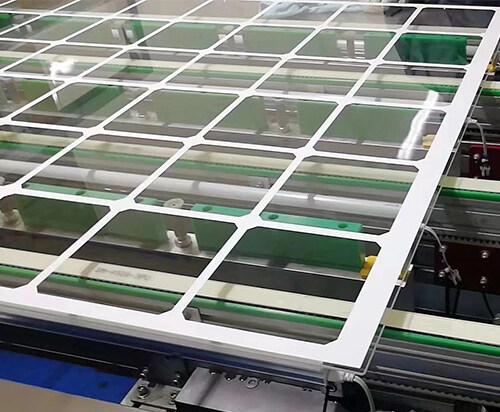

Range Application

Wannan samfurin gabaɗaya ya dace da tsarin baturi na Perc, Topcon da HJT

Ya dace da lu'ulu'u ɗaya na 210, 186, 166, da 158 ƙayyadaddun bayanai

Siffofin Jiki

| A'a. | Abu | Babban sigogi da alamun aikin |

| 1 | Launi, siffa | Ruwan ruwa mai duhu |

| 2 | PH darajar | 13-14 |

| 3 | yawa | 1.1-1.9g/ml |

| 4 | Yanayin ajiya | Ajiye a zafin jiki nesa da haske |

Umarni

1. Add wani dace adadin alkali (1.5 - 2.5% dangane da girma rabo na KOH (48%) a cikin tanki.

2. Ƙara adadin da ya dace na wannan samfurin (0.5 - 0.8% by girma) a cikin tanki.

3. Dumi ruwa na tanki na rubutu zuwa 80 ℃ + 4.

4. Saka silicon wafer a cikin tanki texturing, da kuma dauki lokaci ne 400s-500s.

5, Shawarar nauyi asara ga guda fim: 0.45 + - 0.06 g (210 fim kafofin, sauran fim kafofin suna tuba a daidai rabbai).

Amfani Case

Ɗaukar kayan aikin rubutu irin na Jiejia Veichuang a matsayin misali, ana amfani da tsarin goge goge ba na farko ba.

| Tankin tsari | Ruwa mai tsafta | Alkali (45% KOH) | Bugu da kari (JUNHE®2550) | Lokaci | Zazzabi | Rage nauyi | |

| Rubutun rubutu | Ruwa na farko | 437.5l | 6 l | 2.5 l | 420 na biyu | 82 ℃ | 0.47 ± 0.03gram |

| Jikowar ruwa | 9L | 500 ml | 180 ml |

Matakan kariya

1. Additives bukatar da za a adana tsananin nesa da haske.

2. Lokacin da samar line ba samar, da ruwa ya kamata a replenished da drained kowane minti 30.Idan ba a samar da fiye da sa'o'i 2 ba, ana bada shawara don magudana da sake cika ruwa.

3, New line debugging na bukatar tsari matching bisa ga kowane tsari na samar line kara yadda ya dace.Hanyar da aka ba da shawarar za a iya komawa zuwa gyara kuskure.