Mafi ƙarancin oda:100 kilogiram

Cikakkun bayanai:

Kunshin A:20kg/ Ganga Karfe

Kunshin B: 20KG Filastik Ganga

Kunshin C: Dangane da adadin wakilin B A

Lokacin Bayarwa:Kwanaki goma bayan samun kuɗin gaba

Sharuɗɗan Biyan kuɗi:L/C, T/T

Ikon bayarwa:2 Ton/Tons kowace rana

Launi:Azurfa

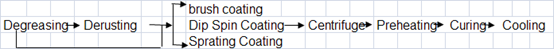

Hanyar Rufewa:Dip And Fesa Shafi

PH (20 ℃):5.0-8.0

Takamaiman Nauyi:1.30-1.40 (shafin fesa)

Dankowa:Dangane da Bukatar Aiki

Yanayin Aiki:22± 2℃

Bayani

JH-9610 yana kunshe da fakiti uku: A,B da C;

Fakitin A: slurry ce ta azurfa wacce akasari ke hade da kemikal tare da super fine flake Zn, super fine flake Al da kwayoyin kari.

Kunshin B: Maganin ruwa ne wanda galibi ya haɗa shi da ƙari na kariya na lalata, ƙayyadaddun tsarin ruwa na musamman da sauransu.

Pack C: Ita ce tackifier na rufi wanda galibi ya ƙunshi farin cellulose ko foda mai launin rawaya.

Halayen Aiki:

1. Chrome kyauta;

2. Good surface gama yi, high anti-lalata, low gogayya coefficient;

3. Babu hydrogen brittleness, babu pickling tsari;

4. Kyakkyawan juriya na zafi;

5. Good SST hours, anti-tsufa sake zagayowar ne dogon, iya gashi more kayayyakin karkashin wannan tsari yanayi.

Tsarin Rufewa

1. Mix Ratio

Kunshin A: Kunshin B: Kunshin C = 1: 1: X (bisa ga buƙatun danko daban-daban)

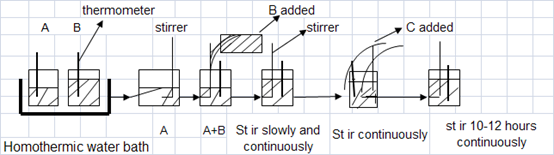

2. Kafin Cakuda, Ci gaba da nauyi A & B cikin ruwa wanka a 25 ± 2 ℃ , sa'an nan motsa A don yin karfe slurry tarwatsa uniformly ta mita mahautsini , bayan A ne cikakken ko'ina tarwatsa, rage agitating gudun zuwa 60r / min, da kuma ƙara B .

3. Ƙara B zuwa motsawar A sannu a hankali.

4. Sai azuba ruwan kamar 1 ~ 2 hours bayan B aka kara, sannan a zuba C. C sai a yi powdered idan dunkule ya wanzu. ~12 hours a hankali da kuma ci gaba.

Mix zane

Hankali

1. Sauran sinadarai irin su kowane irin acid, gishirin alkali ba za a iya haɗa su cikin sutura ba, don waɗannan suna iya kunna Zn & Al plate zuwa tsufa.

2. Kauce wa hasarar hasken rana da hasken ultraviolet na dogon lokaci lokacin aiki, in ba haka ba zai hanzarta tsufa ko polymerization na shafi.

3. Yana da matukar mahimmanci don sarrafa yawan zafin jiki na sutura.Idan yawan zafin jiki na rufi ya canza lokacin aiki, zai haifar da danko, sa'an nan kuma tasirin tasirin shafi akan workpiece.Don haka dangantakar da ke tsakanin zafin jiki, danko da tsarin juyi yakamata a sarrafa su da kyau yayin rufewa.

4. Danko zai bambanta idan hanyar shafi ta bambanta.Zaɓi ƙananan bayanai idan suturar feshi, kuma zaɓi babban bayanai idan tsoma suturar juyawa.

Bayanan Fasaha

| A'a. | Abu | Bayanai |

| 1 | Launi | Azurfa |

| 2 | Hanyar sutura | Diping & Spraying |

| 3 | PH | 4.8-7.5 |

| 4 | Musamman nauyi | 1.45 ± 0.1 (shafin fesa) |

| 5 | Dankowar jiki | 25 ~ 40s (shafin fesa) |